Over the last decade, the solar industry has witnessed a number of remarkable technical and economic landmarks which—apart from creating important environmental benefits—have also placed energy-independence within the reach of homeowners and businesses across America.

Commercially available solar panels with record-breaking efficiencies of over 20%.

Average annual market growth exceeding 35%.

Enormous reductions in manufacturing costs that have lowered the per/Watt cost of solar power to below grid rates.

Investment payback times now as low as 1-year or less.

As you might expect, far from creating complacence, all this extraordinary news has made solar energy research even more attractive, spurring scientists to find ways to make solar power an even better bargain.

The problem is that there’s not much left to do by way of improving the performance of commercially manufactured silicon solar cells as they’re standardly constructed.

Impurities in the silicon, which once impeded energy production, have been eliminated. And the two silicon wafers which make up a solar cell have become so thin that further reductions in size, even if possible, won’t lower costs much.

Because of these successes, scientists had to look for ways to increase the efficiency of solar cells by changing their design. So, they turned to an idea first developed by Australian scientist Martin Green way back in the 80s called Passivated rear emitter contact solar cell, or PERC for short.

The results were nothing short of breathtaking. The bit manufacturers started producing PERC solar panels in 2019. Within just one year, PERC completely dominated the market, accounting for a whopping 80% of all silicon solar panels produced in 2020.

Within the next few years, traditional silicon solar panels are likely to become as obsolete as floppy disk drives. So, what makes PERC solar panels so great?

Silicon Solar Cells

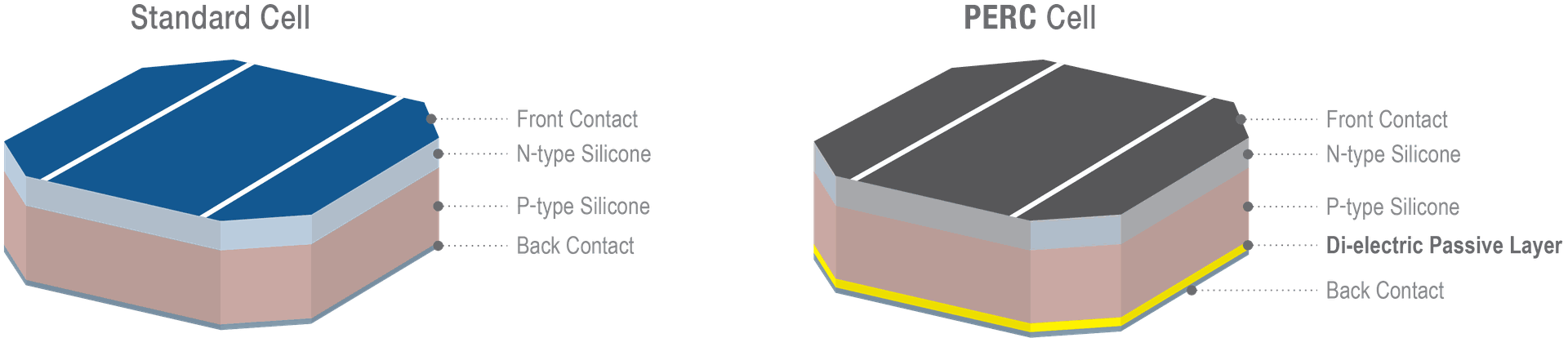

The standard solar cell is composed of two layers of silicon, each slightly altered in a different way.

The top layer is composed of n-type silicon, which has been altered or doped by injecting phosphorus. Phosphorus has one more electron in its outer shell than silicon. So, phosphorus doping gives the top layer of a solar cell extra negatively charged electrons.

The bottom layer of a solar cell, on the other hand, is made of p-type silicon, usually doped with boron. Boron has one less electron in its outer shell than silicon. This means the bottom layer is missing electrons, which creates positively charged holes in molecules.

Light is composed of infinitesimally small particles called photons. When sunlight strikes a solar cell, some of the photons collide with some of the extra electrons from the top layer and “knock” them loose. These electrons are then drawn to the electron-deprived bottom layer through a connecting wire and, voilà!, electrical current is created.

Two Problems with Standard Cells

But there are two ways in which standard silicon solar cells are inefficient.

Some of the sun’s photons pass completely through the panel without striking any electrons. Apart from not generating any current, they also cause the back of the panel to heat up, which leads to a further loss in the amount of current generated.

Some of the electrons that get knocked loose—instead of continuing to flow through the system—will recombine with the electron-deprived holes at the bottom surface of the solar cell, decreasing the amount of current generated.

The PERC Solution

A PERC solar panel is just a standard silicon-based panel with an additional layer added to the bottom that helps solve both problems.

The PERC layer is reflective. So, instead of causing efficiency-reducing heat at the back, photons of light that pass through the panel get bounced back, giving them another chance to “knock” an electron free and generate more current.

The PERC layer is also dielectric. That means that, though it’s an insulator and no electricity can pass through it, it nonetheless has an electrical charge which will repel electrons in adjacent objects. That repelling force stops the electrons flowing through the system from recombining with the electron-deprived holes at the bottom of the panel, so they keep flowing freely through the system and producing current.

Extra Power Without Extra Cost

A system composed of PERC panels will generate around 5% more energy than one using standard panels. So, for example, if it would take 40 standard panels to meet a homeowner’s energy needs, you could generate the same amount of energy with only 38 PERC panels.

That may not seem like a lot, but fewer panels also mean fewer microinverters, as well as less racking, wiring, and labor.

Moreover, manufacturers have been largely able to reuse existing production equipment when they produce PERC panels. So, it’s turned out that any additional manufacturing cost is more than compensated by their increased efficiency.

And that’s why, in just one year, PERC solar panels have gone from being an unapplied theoretical concept to the solar industry’s standard tech.